A Forensic Guide to Delamination on RVs, Boats and Off-Grid Systems

Introduction: When “Flexible” Starts to Peel

If you spend enough time in RV parks or marinas, you’ve seen it: a solar panel that looks like it’s suffering from a bad sunburn. The top layer is bubbling, the surface looks milky, or the plastic film is peeling off in sheets.

We hear the same question constantly at LinkSolar: “My panels are still producing power, but the top film is bubbling or peeling. Did the ETFE fail?”

The short answer is usually no. The ETFE film itself hasn't failed; the adhesive system holding the panel together has. What you are seeing is a failure of the lamination process, often accelerated by extreme heat.

In this forensic guide, we’ll look past the cosmetic symptoms and dig into the root causes—specifically why the adhesive layers break down—and how to choose high-quality replacement flexible solar panels that are built to last.

1. The ETFE Myth — Film vs. Adhesive

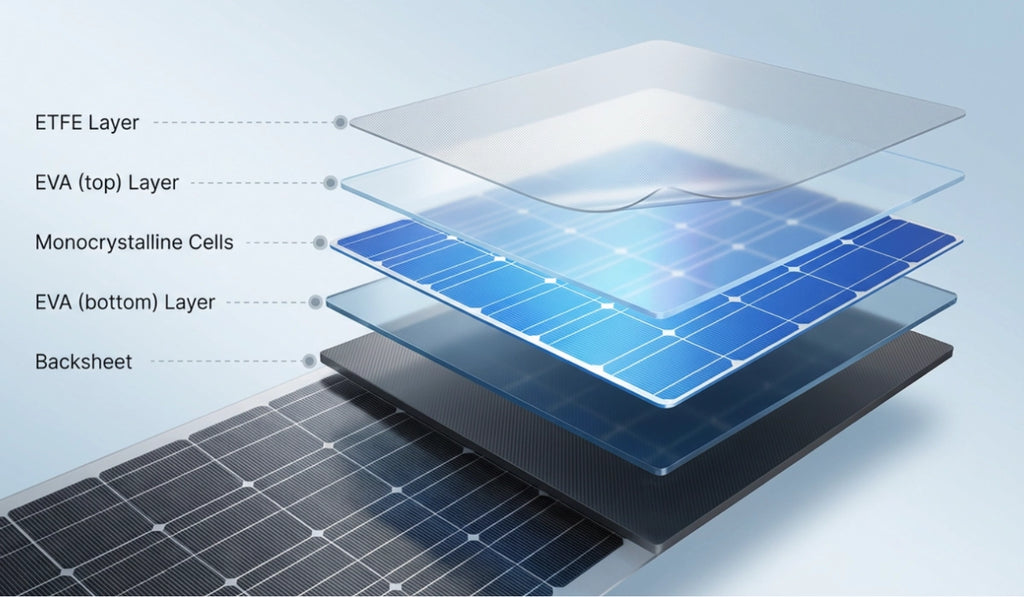

First, we need to clear up a misconception. In the world of flexible solar, the top film is your first line of defense. High-quality panels use ETFE (Ethylene Tetrafluoroethylene) because it is tough, self-cleaning, and transparent. Cheap alternatives use PET, which is essentially the same plastic as a water bottle.

Note: ETFE is a fluorine-based plastic designed for high corrosion resistance and strength over a wide temperature range.

If your panel turns chalky and brittle within 1–3 years, you were likely sold a PET panel. However, when you see a high-quality ETFE panel peeling, the film itself is often still intact. What has failed is the bond underneath it.

It’s Not the Skin, It’s the Glue

ETFE is a non-stick material. Getting it to stick to solar cells requires a specialized lamination process using an encapsulant, usually EVA. When a panel delaminates, it is a failure of the interface between the ETFE and the EVA. This shifts the blame from the "plastic" to the temperature and installation conditions.

2. Visual Forensics: What to Look For

Delamination is a progressive disease. On a boat deck or RV roof, it usually follows this pattern:

- The Edge Lift: Moisture wicks in at the corners.

- The "Milky" Haze: The EVA chemically degrades, losing transparency.

- Blistering: Raised bubbles appear, especially over the hotter solar cells.

- Total Separation: The wind catches a loose edge, ripping the film away.

3. The Root Causes: Heat & Chemistry

3.1 The "Deadly Hug" (Installation & Heat)

We love flexible panels because they can be mounted on curved surfaces. But gluing them flat to a heat-conducting roof without airflow is a primary cause of failure.

In full summer sun, a direct-bonded panel can reach 85°C (185°F). At these temperatures, the EVA encapsulant softens and loses mechanical strength. For specialized applications where heat is a major concern, we often recommend our partners consider custom solar panel solutions that allow for specific mounting structures or backing materials.

3.2 The Vinegar Effect (Hydrolysis)

When moisture creeps into the panel edges—common on boats—the EVA undergoes hydrolysis. It breaks down and produces acetic acid (vinegar). This acid eats away at the internal bonds and corrodes the solar cells. This is often visible as "snail trails" (dark lines) across the cell surface.

4. The Safety Risk: Hotspots and Fire

Is a peeling panel just ugly? No, it’s a safety hazard. When a bubble forms over a cell, it traps heat and blocks light. That cell stops generating power and starts consuming it, creating a "hotspot." We have seen backsheets burned through because of this.

5. How to Diagnose Your Panels (Safely)

You don’t need a lab to check your system. A visual inspection and a multimeter are enough.

- Check Voltage (Voc): Disconnect the panel. It should be close to the rated Voc.

- Check Current (Isc) - ⚠️ CAUTION: Solar panels are always "live" in the sun. Before measuring current, cover the panel. Connect your multimeter, then uncover it to avoid dangerous electrical arcs.

If your Voltage is normal but Current is 30-50% lower, the panel is delaminating internally. It is time to replace it.

6. Real Talk: Price vs. Lifespan

You can find flexible solar panels on marketplaces for very low prices. But typically, these panels use standard EVA and have a service life of only 3 to 5 years in harsh conditions.

We encourage our customers to think about the cost of replacement labor. Removing old adhesive is difficult work. It is worth investing in panels from a reputable manufacturer like LinkSolar that uses verified ETFE and stable encapsulants.

Summary: Buy Smart, Install Smarter

You can’t undo delamination once it starts. But for your next setup:

- Verify Materials: Ensure you are buying genuine ETFE.

- Manage Heat: Use spacers or polycarbonate sheets to create airflow.

- Choose Quality: Don't just look at the price tag; look at the materials.

If your current panels are showing signs of failure, don’t wait for a safety hazard. Contact our engineering team today for a professional recommendation on a durable replacement that fits your specific footprint.